This leg is also sold on Trident Tables – Call for Details.

Leg Details – Sold a a set

Product #: TVW-A24-305-42

Product Name: Banquet Style Table Legs – Adjustable Folding Table Leg-TVW-A24-305-42 Non-Overlapping

Description: This style leg is popular for round or rectangular style tables. Legs come standard with black hammertone powder coat finish and zinc finish.

FEATURES:

24″ footprint non-overlapping adjustable Wishbone

Adjustable with spring mechanism from 30″ to 42″ in 1″ incriments (with a 3/4 table top, this leg set makes a 30-42 inch tall table)

1 inch and 1 1/8 inch tube in #18 gauge round tubular steel

Finish: two-tone finish — Upper section: Matte black powder coating — Lower section: Zinc plated (chrome plating available for additional cost)

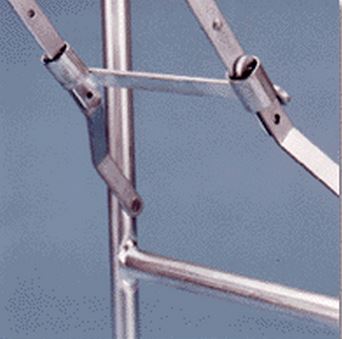

#8 gauge Dura-Lok hinge assembly system

Plastic floor glides (included, not installed)

Black hammertone powder coat finish standard with zinc

Best Applications: Tables

How are the Folding Legs made? And why are they the best value in the market?

We take pride in making the highest quality legs made in the USA. Each For example, the riveting process has been developed for solid rivets. The highest quality processes are used to ensure attractive legs and legs that will be durable for many years.

The American craftsmen who make our legs use the newest technology some of the most sophisticated equipment in the industry. This state of the art equipment, in conjunction with a skilled staff of welders and machinist-craftsmen who have spent years refining their skills. This has made us the leader in metal fabrication. The average employee has a minimum of fifteen years experience, and that experience translates into high quality. They take pride in quality banquet table legs, right here in the USA.

Sur-Lok Gravity Locking System

Folding table legs need to stay folded. We are dedicated to high quality and safety. The Sur-Lok gravity locking system is standard on our legs to insure they offer years of wear and security. Just pull the table legs into position, turn the table over, and the locking system will engage and stay engaged.

Welding – Full Cirumference Welding

Welding table legs is a diversified process. Many companies cut costs by using cheap manufacturing methods. We are more concerned with quality products that will be durable for years, than cutting costs.

On non-adjustable legs, the cross member to leg weld is a full 360º MIG Weld. This is critical in the stability of the table. The type of weld is an integral part to the continued use of the hinge assembly: If the weld fails the product is useless. We insert the cross-member into the stamped opening, and only then is this weld applied. We are committed to a product that performs fold after fold. This high quality weld offers that assurance.

Full Radial Rivets

RADIAL RIVETS

The importance of manufacturing the highest quality product is demonstrated clearly in the detail that we utilize in the manufacturing process. Every aspect is carefully thought out and planned to achieve the best possible folding table legs. We use 3/16″ solid steel rivets in the hinge assembly (not semi-tubular rivets). The added benefit is long term durability and strength. The table leg is further strengthened at the top L bracket and the hinge assembly to leg assembly with ¼” solid steel rivets. Radial riveting ensures their integrity and contributes to the sleek appearance of the assembly. This process complements the look of the finished product.

Quality Powder Finish

Our folding legs are available (all non-adjustable table legs and risers) with an attractive, durable, high quality black hammertone powder coat finish. Powder coated surfaces are more resistant to corrosion and fading, therefore the finish stays bright and vibrant longer than traditional zinc plated finishes. Additionally powder coated surfaces are more resistant to chipping, scratching and wear than other finishes.

]]>Product #: TVW30-305

Product Name: Banquet Style Table Legs – Non-Overlapping

Description: This style leg is popular for round or rectangular style tables. Legs come standard with black hammertone powder coat finish.

FEATURES:

30″ footprint non-overlapping Wishbone

30″ tall (with a 3/4 table top, this leg set makes a 3o inch tall table)

1 inch tube in #16 gauge round tubular steel

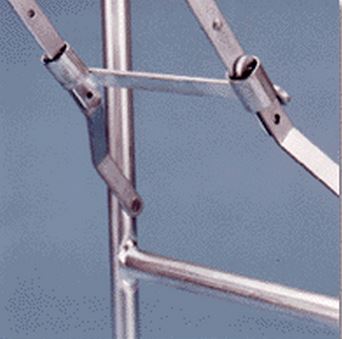

#8 gauge Dura-Lok hinge assembly system

Dual Dimple locking mechanism

Plastic floor glides (included, not installed)

black hammertone powder coat finish standard

Best Applications: Tables

How are the Folding Legs made? And why are they the best value in the market?

MetalKraft takes pride in making the highest quality legs made in the USA. Each For example, the riveting process has been developed for solid rivets. The highest quality processes are used to ensure attractive legs and legs that will be durable for many years.

The American craftsmen who make MetalKraft legs use the newest technology some of the most sophisticated equipment in the industry. This state of the art equipment, in conjunction with a skilled staff of welders and machinist-craftsmen who have spent years refining their skills. This has made MetalKraft the leader in metal fabrication. The average employee has a minimum of fifteen years experience, and that experience translates into high quality. They take pride in quality banquet table legs, right here in the USA.

Sur-Lok Gravity Locking System

Folding table legs need to stay folded. MetalKraft is dedicated to high quality and safety. The Sur-Lok gravity locking system is standard on MetalKraft legs to insure they offer years of wear and security. Just pull the table legs into position, turn the table over, and the locking system will engage and stay engaged.

Welding – Full Cirumference Welding

Welding table legs is a diversified process. Many companies cut costs by using cheap manufacturing methods. MetalKraft is more concerned with quality products that will be durable for years, than cutting costs.

On non-adjustable legs, the cross member to leg weld is a full 360º MIG Weld. This is critical in the stability of the table. The type of weld is an integral part to the continued use of the hinge assembly: If the weld fails the product is useless. MetalKraft inserts the cross-member into the stamped opening, and only then is this weld applied. MetalKraft is committed to a product that performs fold after fold. This high quality weld offers that assurance.

Full Radial Rivets

RADIAL RIVETS

The importance of manufacturing the highest quality product is demonstrated clearly in the detail that MetalKraft utilizes in the manufacturing process. Every aspect is carefully thought out and planned to achieve the best possible folding table legs. MetalKraft utilizes 3/16″ solid steel rivets in the hinge assembly (not semi-tubular rivets). The added benefit is long term durability and strength. The table leg is further strengthened at the top L bracket and the hinge assembly to leg assembly with ¼” solid steel rivets. Radial riveting ensures their integrity and contributes to the sleek appearance of the assembly. This process complements the look of the finished product.

Quality Powder Finish

Our folding legs are available (all non-adjustable table legs and risers) with an attractive, durable, high quality black hammertone powder coat finish. Powder coated surfaces are more resistant to corrosion and fading, therefore the finish stays bright and vibrant longer than traditional zinc plated finishes. Additionally powder coated surfaces are more resistant to chipping, scratching and wear than other finishes. MetalKraft Folding Legs Rock.

use as template

]]>