TPV-RT4272 – 6’x42″ Plywood Folding Table

The V-Series tables are Made in the USA from USA materials and will provide years of service.

Please call if your order is fewer than the minimum order quantity or more than 20 tables so we can get you a custom quote.

Quick Specs for the V-series Plywood Tables

29 inch table height.

Plywood Specifications

Type of Plywood — The V-Series uses Doug Fir known for its strength and durability. Origin of the Plywood—Western USA forests.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Domestic plywood is 23”/32”, but as a rule of thumb it is called ¾”. Normally 7 plies

Plywood used in the V series tables is Douglas Fir. 100% USA Made plywood.

The Trident V-Series Doug Fir Quick Specs

Number of plies – 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.7

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Structure is tight lay up. Each ply is cross-layered

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Compare to Common Import Specs

Number of plies – 11 – 13

Face veneer is very thin – 1/32″

Structure is not tight lay up

Not all layers of plies are cross layered

Some mills use cheaper interior glue

V-Series Plywood vs. Import pros and cons.

V series wood plies are thicker layers giving added strength

Imported thin veneers tends to delaminate and is not easily repairable like a thicker veneer.

V-Series tight lay up eliminates internal voids that may weaken the plywood and cross layering of each ply gives added strength

V-Series exterior glue is required to prevent moisture delamination. Who really knows what type of glue on imports.

Surface Finish of the Plywood

All the V-Series tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for your table. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

How Many Coats of Polyurethane?

Two coats – Polyurethane is a generic term used in the industry to describe the coating; however, Trident V-Series Tables uses an industrial lacquer. It is actually an industrial lacquer that has a catalyst added for hardness and fast drying time. After the catalyst is added the product must be used within a three (3) month period. It is an oil base that is more resistant to water; also, one (1) coat of oil base stain is applied to top and bottom of table.

What Type of Runners?

Wood Species: Runners are made from American hard wood (typically white ash, oak or beech)

Thickness: Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Securing the Runner: Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keeps nut)

The V-series table hard wood table runners are shown below, fully bolted through the top tp provide durability. Many tables use screws that are not as durable.

Above: Hard wood runners and bolted all through for strength and durability

Shown below: Strong hard wood runners on the under side of the table.

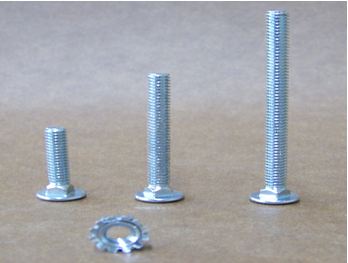

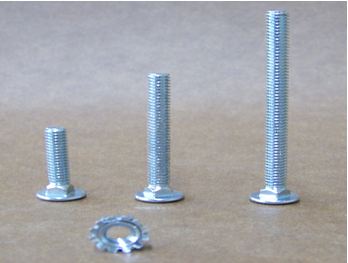

Bolts used on V-Series Plywood Folding Tables

Runner Bolts and their Length

Legs: Leg bolts on all tables are 1-1/4″

Runner Bolts:

1. On Rectangular Banquet Tables that are 6’ and 8’ the runner bolts are 2-3/16”.

2. Runner bolts on banquet tables shorter than 6’ are 3-3/16”.

3. All Round Table runner bolts are 3-3/16”.

Longer bolts are required on shorter tables because the length required to overlay legs. See picture below. All table bolts are secured with a self locking nut called a “Keps Nut”

Shown Below: Overlay means that one leg must be folded first and then the second leg must be folded to lie on top of the first leg.

What Edge Protections Are Available?

The Standard molding is a bullnose molding. Bullnose is actually a profile and is used to describe a rounded over edge. It is referred to in the industry as rubber, but ours is actually a vinyl product. Our Vinyl is tough and durable, but because vinyl is also temperature sensitive and expands with heat and contracts with cold, our craftsmen pin the vinyl molding to the table every 12” and triple pins the corners. This makes for a long lasting and durable bullnose edge.

Both moldings shown here are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood.

Shown Below: Vinyl Bullnose T-molding

Aluminum “C” Channel (shown below) is an option that some customers prefer. The V series uses aluminum T4, which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Both moldings are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood. The aluminum edge is a highly durable and slightly more expensive edge option and must be specified on your order and upcharged. Vinyl bullnose is used as a standard option.

Folding Table Legs

All V-Series Table legs are made of 16 gauge 1” cold rolled steel. Gauge describes the wall thickness of the tube. The higher the gauge number the thinner the wall thickness.

For example 18 gauge is thinner than 16 gauge. Quality of steel in all imported items is an ongoing problem. American made steel is reliable.

Table legs get abused regularly, so it is very important to understand the components of a table leg.

Rivets (shown below) are the key in the longevity of a leg. Some manufacturers use semi-tubular rivets that are hollow and weaker than solid rivets. Solid rivets naturally cost more but are well worth the assurance that rivets are not breaking when legs and hinges are pivoting constantly. Bracket and hinge assembly is attached with 1/4″ diameter rivets. All V-Series Tables uses all solid rivets. Even the Hinge mechanism rivets are full 3/16″ diameter solid.

The Little Details, like solid core rivits (shown below) make for a High Quality Folding Leg Table.

Leg welds: (Shown Below) All cross tubes are extended through the leg tube walls and the complete circumference is welded. Some manufacturers stop the cross tube at the leg wall and this is call butt welding, meaning there is no support for the cross tube.

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware! To trim costs, some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Durable Hinge Components and Construction

Below: Hinge mechanisms are called Boss and Mate, meaning legs are locked when both open and closed. All legs are powder coated in-house. Powder coating is a static electric process whereby powder clings to the steel legs and then gets baked and cured at high temperatures to bond to the steel. Colors can be specified.

Floor Protection

Heavy duty end caps resist wear and protect floors.

This part of the table should not be overlooked, but often is. Carpet, wood floors and vinyl floors can be severely damaged with low cost caps or plugs. Check your tables regularly.

Below is a full FAQ with more info to consider.

Questions to Ask when Buying a Plywood Table

The PLYWOOD part of the story

Type of Plywood — The V-Series uses Doug Fir plywood, known worldwide for its strength and durability. Origin of the Plywood—Western USA forests.

Beware ! Your table may be made from imported plywood from an unknown Asian country or via China, which lowers the cost but sacrifices quality which leads to problems down the road.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Beware ! Your table may have as many as 11-13 layers, not all plies being cross layered and structure of the layers not a tight lay up which leads to voids and weakens the plywood.

Plywood Thickness–3/4 inch

Beware ! Your table may be made from 5/8 inch plywood which is not as durable or as strong.

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Beware ! The face veneer on your table may be paper thin meaning it will damage easy, is non repairable and tends to warp and delaminate in damp conditions.

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Beware ! Some imported plywood is now using interior glue.

PLYWOOD IS THE FOUNDATION OF YOUR TABLE—BE SURE YOU KNOW ALL THE FACTS. Be sure you know what you are buying—ask for a cut out sample of the plywood. If they are unwilling to supply you with the sample, maybe there is a reason.

Surface Finish of the Plywood—All the V-Series plywood tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for the V-Series tables. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

Beware ! What chemistry is being used and how is your table being finished to assure longevity?

RUNNERS:

Wood Species — Runners are made from American hard wood (typically white ash, oak or beech)

Beware ! Are you getting runners made from hard wood or a soft species such as pine or plywood which sacrifices strength for cost?

Thickness—Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Beware ! Is the height or thickness of the runner being compromised to lower cost but sacrifice strength and lead to potential warping issues.

Securing the Runner—Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keps nut)

Beware ! Be sure your runners are through bolted to provide durability versus using screws.

LEGS

Material: The V-Series table legs are made in house from 16 gauge cold rolled steel.

Beware ! Are your table legs 16 gauge or are they 18 gauge or higher? Remember the higher the gauge the thinner the wall thickness. Do you want to sacrifice the foundation of your table for cost?

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware ! To trim cost some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Components: Rivets although small are very important to the longevity of the leg. The V-Series tables have 1/4” solid rivets to attach the bracket and hinge mechanisms. This helps assure that rivets are not breaking when the leg and hinge is constantly pivoting.

Beware ! Do the legs on your table have solid rivets or are they semi tubular rivets that are hollow and much weaker than the solid rivets? Do you want to sacrifice cost to increase the odds of the table collapsing?

Bolts (1 ¼”) using a special self locking nut (keps nut) are used to through bolt the leg to the table.

Beware ! Are your legs being through bolted for strength or being attached using only screws?

Finish is an in house powder coating which is a static electric process whereby powder is applied to the leg and is baked and cured at a high temperature.

Beware ! What type of finish is on your leg? Does it have the longevity of powder coating?

Leg End Caps are heavy duty, wear resistant and protect the floor. The caps have a special reverse metal gripping mechanism that are inserted into the leg tubing and nylon bottom for floor protection

Beware ! Are the caps being supplied with a special gripping device or being held by tension only?

EDGE MOLDING

Bullnose: Standard molding is bullnose which is referred to as rubber in the industry but is actually a vinyl product which means it is temperature sensitive. That is why we pin the vinyl molding every 12” and triple pin the corners.

Beware ! What action is being taken to assure the bullnose molding will not come loose on your table in extreme temperature changes?

C Channel: Optional aluminum T4 which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Beware ! What grade of C Channel are you being supplied? Is the channel being notched on the corners?

WARRANTY

Duration: Limited Three Year Warranty

Beware ! What is the length of your table warranty? But do you really want to deal with a warranty?

Buy a table that is made with quality materials, in such a way as to make it very unlikely that you will have to hassle with a warranty. Most warranties require you pay he shipping. Shipping can cost more than a table and it’s all an annoyance. Buy the Trident V-Series Plywood Table and avoid the hassle.

]]>

TPV-RT3672 – 6’x36″ Plywood Folding Table

The V-Series tables are Made in the USA from USA materials and will provide years of service.

Please call if your order is fewer than the minimum order quantity or more than 20 tables so we can get you a custom quote.

Quick Specs for the V-series Plywood Tables

Plywood Specifications

Type of Plywood — The V-Series uses Doug Fir known for its strength and durability. Origin of the Plywood—Western USA forests.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Domestic plywood is 23”/32”, but as a rule of thumb it is called ¾”. Normally 7 plies

Plywood used in the V series tables is Douglas Fir. 100% USA Made plywood.

The Trident V-Series Doug Fir Quick Specs

Number of plies – 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.7

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Structure is tight lay up. Each ply is cross-layered

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Compare to Common Import Specs

Number of plies – 11 – 13

Face veneer is very thin – 1/32″

Structure is not tight lay up

Not all layers of plies are cross layered

Some mills use cheaper interior glue

V-Series Plywood vs. Import pros and cons.

V series wood plies are thicker layers giving added strength

Imported thin veneers tends to delaminate and is not easily repairable like a thicker veneer.

V-Series tight lay up eliminates internal voids that may weaken the plywood and cross layering of each ply gives added strength

V-Series exterior glue is required to prevent moisture delamination. Who really knows what type of glue on imports.

Surface Finish of the Plywood

All the V-Series tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for your table. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

How Many Coats of Polyurethane?

Two coats – Polyurethane is a generic term used in the industry to describe the coating; however, Trident V-Series Tables uses an industrial lacquer. It is actually an industrial lacquer that has a catalyst added for hardness and fast drying time. After the catalyst is added the product must be used within a three (3) month period. It is an oil base that is more resistant to water; also, one (1) coat of oil base stain is applied to top and bottom of table.

What Type of Runners?

Wood Species: Runners are made from American hard wood (typically white ash, oak or beech)

Thickness: Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Securing the Runner: Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keeps nut)

The V-series table hard wood table runners are shown below, fully bolted through the top tp provide durability. Many tables use screws that are not as durable.

Above: Hard wood runners and bolted all through for strength and durability

Shown below: Strong hard wood runners on the under side of the table.

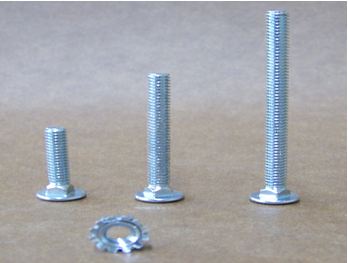

Bolts used on V-Series Plywood Folding Tables

Runner Bolts and their Length

Legs: Leg bolts on all tables are 1-1/4″

Runner Bolts:

1. On Rectangular Banquet Tables that are 6’ and 8’ the runner bolts are 2-3/16”.

2. Runner bolts on banquet tables shorter than 6’ are 3-3/16”.

3. All Round Table runner bolts are 3-3/16”.

Longer bolts are required on shorter tables because the length required to overlay legs. See picture below. All table bolts are secured with a self locking nut called a “Keps Nut”

Shown Below: Overlay means that one leg must be folded first and then the second leg must be folded to lie on top of the first leg.

What Edge Protections Are Available?

The Standard molding is a bullnose molding. Bullnose is actually a profile and is used to describe a rounded over edge. It is referred to in the industry as rubber, but ours is actually a vinyl product. Our Vinyl is tough and durable, but because vinyl is also temperature sensitive and expands with heat and contracts with cold, our craftsmen pin the vinyl molding to the table every 12” and triple pins the corners. This makes for a long lasting and durable bullnose edge.

Both moldings shown here are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood.

Shown Below: Vinyl Bullnose T-molding

Aluminum “C” Channel (shown below) is an option that some customers prefer. The V series uses aluminum T4, which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Both moldings are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood. The aluminum edge is a highly durable and slightly more expensive edge option and must be specified on your order and upcharged. Vinyl bullnose is used as a standard option.

Folding Table Legs

All V-Series Table legs are made of 16 gauge 1” cold rolled steel. Gauge describes the wall thickness of the tube. The higher the gauge number the thinner the wall thickness.

For example 18 gauge is thinner than 16 gauge. Quality of steel in all imported items is an ongoing problem. American made steel is reliable.

Table legs get abused regularly, so it is very important to understand the components of a table leg.

Rivets (shown below) are the key in the longevity of a leg. Some manufacturers use semi-tubular rivets that are hollow and weaker than solid rivets. Solid rivets naturally cost more but are well worth the assurance that rivets are not breaking when legs and hinges are pivoting constantly. Bracket and hinge assembly is attached with 1/4″ diameter rivets. All V-Series Tables uses all solid rivets. Even the Hinge mechanism rivets are full 3/16″ diameter solid.

The Little Details, like solid core rivits (shown below) make for a High Quality Folding Leg Table.

Leg welds: (Shown Below) All cross tubes are extended through the leg tube walls and the complete circumference is welded. Some manufacturers stop the cross tube at the leg wall and this is call butt welding, meaning there is no support for the cross tube.

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware! To trim costs, some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Durable Hinge Components and Construction

Below: Hinge mechanisms are called Boss and Mate, meaning legs are locked when both open and closed. All legs are powder coated in-house. Powder coating is a static electric process whereby powder clings to the steel legs and then gets baked and cured at high temperatures to bond to the steel. Colors can be specified.

Floor Protection

Heavy duty end caps resist wear and protect floors.

This part of the table should not be overlooked, but often is. Carpet, wood floors and vinyl floors can be severely damaged with low cost caps or plugs. Check your tables regularly.

Below is a full FAQ with more info to consider.

Questions to Ask when Buying a Plywood Table

The PLYWOOD part of the story

Type of Plywood — The V-Series uses Doug Fir plywood, known worldwide for its strength and durability. Origin of the Plywood—Western USA forests.

Beware ! Your table may be made from imported plywood from an unknown Asian country or via China, which lowers the cost but sacrifices quality which leads to problems down the road.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Beware ! Your table may have as many as 11-13 layers, not all plies being cross layered and structure of the layers not a tight lay up which leads to voids and weakens the plywood.

Plywood Thickness–3/4 inch

Beware ! Your table may be made from 5/8 inch plywood which is not as durable or as strong.

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Beware ! The face veneer on your table may be paper thin meaning it will damage easy, is non repairable and tends to warp and delaminate in damp conditions.

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Beware ! Some imported plywood is now using interior glue.

PLYWOOD IS THE FOUNDATION OF YOUR TABLE—BE SURE YOU KNOW ALL THE FACTS. Be sure you know what you are buying—ask for a cut out sample of the plywood. If they are unwilling to supply you with the sample, maybe there is a reason.

Surface Finish of the Plywood—All the V-Series plywood tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for the V-Series tables. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

Beware ! What chemistry is being used and how is your table being finished to assure longevity?

RUNNERS:

Wood Species — Runners are made from American hard wood (typically white ash, oak or beech)

Beware ! Are you getting runners made from hard wood or a soft species such as pine or plywood which sacrifices strength for cost?

Thickness—Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Beware ! Is the height or thickness of the runner being compromised to lower cost but sacrifice strength and lead to potential warping issues.

Securing the Runner—Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keps nut)

Beware ! Be sure your runners are through bolted to provide durability versus using screws.

LEGS

Material: The V-Series table legs are made in house from 16 gauge cold rolled steel.

Beware ! Are your table legs 16 gauge or are they 18 gauge or higher? Remember the higher the gauge the thinner the wall thickness. Do you want to sacrifice the foundation of your table for cost?

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware ! To trim cost some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Components: Rivets although small are very important to the longevity of the leg. The V-Series tables have 1/4” solid rivets to attach the bracket and hinge mechanisms. This helps assure that rivets are not breaking when the leg and hinge is constantly pivoting.

Beware ! Do the legs on your table have solid rivets or are they semi tubular rivets that are hollow and much weaker than the solid rivets? Do you want to sacrifice cost to increase the odds of the table collapsing?

Bolts (1 ¼”) using a special self locking nut (keps nut) are used to through bolt the leg to the table.

Beware ! Are your legs being through bolted for strength or being attached using only screws?

Finish is an in house powder coating which is a static electric process whereby powder is applied to the leg and is baked and cured at a high temperature.

Beware ! What type of finish is on your leg? Does it have the longevity of powder coating?

Leg End Caps are heavy duty, wear resistant and protect the floor. The caps have a special reverse metal gripping mechanism that are inserted into the leg tubing and nylon bottom for floor protection

Beware ! Are the caps being supplied with a special gripping device or being held by tension only?

EDGE MOLDING

Bullnose: Standard molding is bullnose which is referred to as rubber in the industry but is actually a vinyl product which means it is temperature sensitive. That is why we pin the vinyl molding every 12” and triple pin the corners.

Beware ! What action is being taken to assure the bullnose molding will not come loose on your table in extreme temperature changes?

C Channel: Optional aluminum T4 which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Beware ! What grade of C Channel are you being supplied? Is the channel being notched on the corners?

WARRANTY

Duration: Limited Three Year Warranty

Beware ! What is the length of your table warranty? But do you really want to deal with a warranty?

Buy a table that is made with quality materials, in such a way as to make it very unlikely that you will have to hassle with a warranty. Most warranties require you pay he shipping. Shipping can cost more than a table and it’s all an annoyance. Buy the Trident V-Series Plywood Table and avoid the hassle.

]]>

TPV-RT4296 – 8’x42″ Plywood Folding Table

The V-Series tables are Made in the USA from USA materials and will provide years of service.

Please call if your order is fewer than the minimum order quantity or more than 20 tables so we can get you a custom quote.

Quick Specs for the V-series Plywood Tables

Plywood Specifications

Type of Plywood — The V-Series uses Doug Fir known for its strength and durability. Origin of the Plywood—Western USA forests.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Domestic plywood is 23”/32”, but as a rule of thumb it is called ¾”. Normally 7 plies

Plywood used in the V series tables is Douglas Fir. 100% USA Made plywood.

The Trident V-Series Doug Fir Quick Specs

Number of plies – 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.7

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Structure is tight lay up. Each ply is cross-layered

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Compare to Common Import Specs

Number of plies – 11 – 13

Face veneer is very thin – 1/32″

Structure is not tight lay up

Not all layers of plies are cross layered

Some mills use cheaper interior glue

V-Series Plywood vs. Import pros and cons.

V series wood plies are thicker layers giving added strength

Imported thin veneers tends to delaminate and is not easily repairable like a thicker veneer.

V-Series tight lay up eliminates internal voids that may weaken the plywood and cross layering of each ply gives added strength

V-Series exterior glue is required to prevent moisture delamination. Who really knows what type of glue on imports.

Surface Finish of the Plywood

All the V-Series tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for your table. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

How Many Coats of Polyurethane?

Two coats – Polyurethane is a generic term used in the industry to describe the coating; however, Trident V-Series Tables uses an industrial lacquer. It is actually an industrial lacquer that has a catalyst added for hardness and fast drying time. After the catalyst is added the product must be used within a three (3) month period. It is an oil base that is more resistant to water; also, one (1) coat of oil base stain is applied to top and bottom of table.

What Type of Runners?

Wood Species: Runners are made from American hard wood (typically white ash, oak or beech)

Thickness: Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Securing the Runner: Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keeps nut)

The V-series table hard wood table runners are shown below, fully bolted through the top tp provide durability. Many tables use screws that are not as durable.

Above: Hard wood runners and bolted all through for strength and durability

Shown below: Strong hard wood runners on the under side of the table.

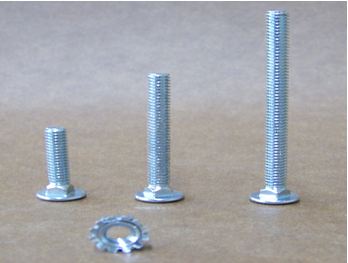

Bolts used on V-Series Plywood Folding Tables

Runner Bolts and their Length

Legs: Leg bolts on all tables are 1-1/4″

Runner Bolts:

1. On Rectangular Banquet Tables that are 6’ and 8’ the runner bolts are 2-3/16”.

2. Runner bolts on banquet tables shorter than 6’ are 3-3/16”.

3. All Round Table runner bolts are 3-3/16”.

Longer bolts are required on shorter tables because the length required to overlay legs. See picture below. All table bolts are secured with a self locking nut called a “Keps Nut”

Shown Below: Overlay means that one leg must be folded first and then the second leg must be folded to lie on top of the first leg.

What Edge Protections Are Available?

The Standard molding is a bullnose molding. Bullnose is actually a profile and is used to describe a rounded over edge. It is referred to in the industry as rubber, but ours is actually a vinyl product. Our Vinyl is tough and durable, but because vinyl is also temperature sensitive and expands with heat and contracts with cold, our craftsmen pin the vinyl molding to the table every 12” and triple pins the corners. This makes for a long lasting and durable bullnose edge.

Both moldings shown here are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood.

Shown Below: Vinyl Bullnose T-molding

Aluminum “C” Channel (shown below) is an option that some customers prefer. The V series uses aluminum T4, which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Both moldings are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood. The aluminum edge is a highly durable and slightly more expensive edge option and must be specified on your order and upcharged. Vinyl bullnose is used as a standard option.

Folding Table Legs

All V-Series Table legs are made of 16 gauge 1” cold rolled steel. Gauge describes the wall thickness of the tube. The higher the gauge number the thinner the wall thickness.

For example 18 gauge is thinner than 16 gauge. Quality of steel in all imported items is an ongoing problem. American made steel is reliable.

Table legs get abused regularly, so it is very important to understand the components of a table leg.

Rivets (shown below) are the key in the longevity of a leg. Some manufacturers use semi-tubular rivets that are hollow and weaker than solid rivets. Solid rivets naturally cost more but are well worth the assurance that rivets are not breaking when legs and hinges are pivoting constantly. Bracket and hinge assembly is attached with 1/4″ diameter rivets. All V-Series Tables uses all solid rivets. Even the Hinge mechanism rivets are full 3/16″ diameter solid.

The Little Details, like solid core rivits (shown below) make for a High Quality Folding Leg Table.

Leg welds: (Shown Below) All cross tubes are extended through the leg tube walls and the complete circumference is welded. Some manufacturers stop the cross tube at the leg wall and this is call butt welding, meaning there is no support for the cross tube.

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware! To trim costs, some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Durable Hinge Components and Construction

Below: Hinge mechanisms are called Boss and Mate, meaning legs are locked when both open and closed. All legs are powder coated in-house. Powder coating is a static electric process whereby powder clings to the steel legs and then gets baked and cured at high temperatures to bond to the steel. Colors can be specified.

Floor Protection

Heavy duty end caps resist wear and protect floors.

This part of the table should not be overlooked, but often is. Carpet, wood floors and vinyl floors can be severely damaged with low cost caps or plugs. Check your tables regularly.

Below is a full FAQ with more info to consider.

Questions to Ask when Buying a Plywood Table

The PLYWOOD part of the story

Type of Plywood — The V-Series uses Doug Fir plywood, known worldwide for its strength and durability. Origin of the Plywood—Western USA forests.

Beware ! Your table may be made from imported plywood from an unknown Asian country or via China, which lowers the cost but sacrifices quality which leads to problems down the road.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Beware ! Your table may have as many as 11-13 layers, not all plies being cross layered and structure of the layers not a tight lay up which leads to voids and weakens the plywood.

Plywood Thickness–3/4 inch

Beware ! Your table may be made from 5/8 inch plywood which is not as durable or as strong.

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Beware ! The face veneer on your table may be paper thin meaning it will damage easy, is non repairable and tends to warp and delaminate in damp conditions.

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Beware ! Some imported plywood is now using interior glue.

PLYWOOD IS THE FOUNDATION OF YOUR TABLE—BE SURE YOU KNOW ALL THE FACTS. Be sure you know what you are buying—ask for a cut out sample of the plywood. If they are unwilling to supply you with the sample, maybe there is a reason.

Surface Finish of the Plywood—All the V-Series plywood tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for the V-Series tables. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

Beware ! What chemistry is being used and how is your table being finished to assure longevity?

RUNNERS:

Wood Species — Runners are made from American hard wood (typically white ash, oak or beech)

Beware ! Are you getting runners made from hard wood or a soft species such as pine or plywood which sacrifices strength for cost?

Thickness—Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Beware ! Is the height or thickness of the runner being compromised to lower cost but sacrifice strength and lead to potential warping issues.

Securing the Runner—Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keps nut)

Beware ! Be sure your runners are through bolted to provide durability versus using screws.

LEGS

Material: The V-Series table legs are made in house from 16 gauge cold rolled steel.

Beware ! Are your table legs 16 gauge or are they 18 gauge or higher? Remember the higher the gauge the thinner the wall thickness. Do you want to sacrifice the foundation of your table for cost?

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware ! To trim cost some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Components: Rivets although small are very important to the longevity of the leg. The V-Series tables have 1/4” solid rivets to attach the bracket and hinge mechanisms. This helps assure that rivets are not breaking when the leg and hinge is constantly pivoting.

Beware ! Do the legs on your table have solid rivets or are they semi tubular rivets that are hollow and much weaker than the solid rivets? Do you want to sacrifice cost to increase the odds of the table collapsing?

Bolts (1 ¼”) using a special self locking nut (keps nut) are used to through bolt the leg to the table.

Beware ! Are your legs being through bolted for strength or being attached using only screws?

Finish is an in house powder coating which is a static electric process whereby powder is applied to the leg and is baked and cured at a high temperature.

Beware ! What type of finish is on your leg? Does it have the longevity of powder coating?

Leg End Caps are heavy duty, wear resistant and protect the floor. The caps have a special reverse metal gripping mechanism that are inserted into the leg tubing and nylon bottom for floor protection

Beware ! Are the caps being supplied with a special gripping device or being held by tension only?

EDGE MOLDING

Bullnose: Standard molding is bullnose which is referred to as rubber in the industry but is actually a vinyl product which means it is temperature sensitive. That is why we pin the vinyl molding every 12” and triple pin the corners.

Beware ! What action is being taken to assure the bullnose molding will not come loose on your table in extreme temperature changes?

C Channel: Optional aluminum T4 which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Beware ! What grade of C Channel are you being supplied? Is the channel being notched on the corners?

WARRANTY

Duration: Limited Three Year Warranty

Beware ! What is the length of your table warranty? But do you really want to deal with a warranty?

Buy a table that is made with quality materials, in such a way as to make it very unlikely that you will have to hassle with a warranty. Most warranties require you pay he shipping. Shipping can cost more than a table and it’s all an annoyance. Buy the Trident V-Series Plywood Table and avoid the hassle.

]]>

TPV-RT4896 – 8’x48″ Plywood Folding Table

The V-Series tables are Made in the USA from USA materials and will provide years of service.

Please call if your order is fewer than the minimum order quantity or more than 20 tables so we can get you a custom quote.

Quick Specs for the V-series Plywood Tables

Plywood Specifications

Type of Plywood — The V-Series uses Doug Fir known for its strength and durability. Origin of the Plywood—Western USA forests.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Domestic plywood is 23”/32”, but as a rule of thumb it is called ¾”. Normally 7 plies

Plywood used in the V series tables is Douglas Fir. 100% USA Made plywood.

The Trident V-Series Doug Fir Quick Specs

Number of plies – 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.7

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Structure is tight lay up. Each ply is cross-layered

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Compare to Common Import Specs

Number of plies – 11 – 13

Face veneer is very thin – 1/32″

Structure is not tight lay up

Not all layers of plies are cross layered

Some mills use cheaper interior glue

V-Series Plywood vs. Import pros and cons.

V series wood plies are thicker layers giving added strength

Imported thin veneers tends to delaminate and is not easily repairable like a thicker veneer.

V-Series tight lay up eliminates internal voids that may weaken the plywood and cross layering of each ply gives added strength

V-Series exterior glue is required to prevent moisture delamination. Who really knows what type of glue on imports.

Surface Finish of the Plywood

All the V-Series tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for your table. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

How Many Coats of Polyurethane?

Two coats – Polyurethane is a generic term used in the industry to describe the coating; however, Trident V-Series Tables uses an industrial lacquer. It is actually an industrial lacquer that has a catalyst added for hardness and fast drying time. After the catalyst is added the product must be used within a three (3) month period. It is an oil base that is more resistant to water; also, one (1) coat of oil base stain is applied to top and bottom of table.

What Type of Runners?

Wood Species: Runners are made from American hard wood (typically white ash, oak or beech)

Thickness: Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Securing the Runner: Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keeps nut)

The V-series table hard wood table runners are shown below, fully bolted through the top tp provide durability. Many tables use screws that are not as durable.

Above: Hard wood runners and bolted all through for strength and durability

Shown below: Strong hard wood runners on the under side of the table.

Bolts used on V-Series Plywood Folding Tables

Runner Bolts and their Length

Legs: Leg bolts on all tables are 1-1/4″

Runner Bolts:

1. On Rectangular Banquet Tables that are 6’ and 8’ the runner bolts are 2-3/16”.

2. Runner bolts on banquet tables shorter than 6’ are 3-3/16”.

3. All Round Table runner bolts are 3-3/16”.

Longer bolts are required on shorter tables because the length required to overlay legs. See picture below. All table bolts are secured with a self locking nut called a “Keps Nut”

Shown Below: Overlay means that one leg must be folded first and then the second leg must be folded to lie on top of the first leg.

What Edge Protections Are Available?

The Standard molding is a bullnose molding. Bullnose is actually a profile and is used to describe a rounded over edge. It is referred to in the industry as rubber, but ours is actually a vinyl product. Our Vinyl is tough and durable, but because vinyl is also temperature sensitive and expands with heat and contracts with cold, our craftsmen pin the vinyl molding to the table every 12” and triple pins the corners. This makes for a long lasting and durable bullnose edge.

Both moldings shown here are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood.

Shown Below: Vinyl Bullnose T-molding

Aluminum “C” Channel (shown below) is an option that some customers prefer. The V series uses aluminum T4, which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Both moldings are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood. The aluminum edge is a highly durable and slightly more expensive edge option and must be specified on your order and upcharged. Vinyl bullnose is used as a standard option.

Folding Table Legs

All V-Series Table legs are made of 16 gauge 1” cold rolled steel. Gauge describes the wall thickness of the tube. The higher the gauge number the thinner the wall thickness.

For example 18 gauge is thinner than 16 gauge. Quality of steel in all imported items is an ongoing problem. American made steel is reliable.

Table legs get abused regularly, so it is very important to understand the components of a table leg.

Rivets (shown below) are the key in the longevity of a leg. Some manufacturers use semi-tubular rivets that are hollow and weaker than solid rivets. Solid rivets naturally cost more but are well worth the assurance that rivets are not breaking when legs and hinges are pivoting constantly. Bracket and hinge assembly is attached with 1/4″ diameter rivets. All V-Series Tables uses all solid rivets. Even the Hinge mechanism rivets are full 3/16″ diameter solid.

The Little Details, like solid core rivits (shown below) make for a High Quality Folding Leg Table.

Leg welds: (Shown Below) All cross tubes are extended through the leg tube walls and the complete circumference is welded. Some manufacturers stop the cross tube at the leg wall and this is call butt welding, meaning there is no support for the cross tube.

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware! To trim costs, some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Durable Hinge Components and Construction

Below: Hinge mechanisms are called Boss and Mate, meaning legs are locked when both open and closed. All legs are powder coated in-house. Powder coating is a static electric process whereby powder clings to the steel legs and then gets baked and cured at high temperatures to bond to the steel. Colors can be specified.

Floor Protection

Heavy duty end caps resist wear and protect floors.

This part of the table should not be overlooked, but often is. Carpet, wood floors and vinyl floors can be severely damaged with low cost caps or plugs. Check your tables regularly.

Below is a full FAQ with more info to consider.

Questions to Ask when Buying a Plywood Table

The PLYWOOD part of the story

Type of Plywood — The V-Series uses Doug Fir plywood, known worldwide for its strength and durability. Origin of the Plywood—Western USA forests.

Beware ! Your table may be made from imported plywood from an unknown Asian country or via China, which lowers the cost but sacrifices quality which leads to problems down the road.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Beware ! Your table may have as many as 11-13 layers, not all plies being cross layered and structure of the layers not a tight lay up which leads to voids and weakens the plywood.

Plywood Thickness–3/4 inch

Beware ! Your table may be made from 5/8 inch plywood which is not as durable or as strong.

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Beware ! The face veneer on your table may be paper thin meaning it will damage easy, is non repairable and tends to warp and delaminate in damp conditions.

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Beware ! Some imported plywood is now using interior glue.

PLYWOOD IS THE FOUNDATION OF YOUR TABLE—BE SURE YOU KNOW ALL THE FACTS. Be sure you know what you are buying—ask for a cut out sample of the plywood. If they are unwilling to supply you with the sample, maybe there is a reason.

Surface Finish of the Plywood—All the V-Series plywood tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for the V-Series tables. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

Beware ! What chemistry is being used and how is your table being finished to assure longevity?

RUNNERS:

Wood Species — Runners are made from American hard wood (typically white ash, oak or beech)

Beware ! Are you getting runners made from hard wood or a soft species such as pine or plywood which sacrifices strength for cost?

Thickness—Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Beware ! Is the height or thickness of the runner being compromised to lower cost but sacrifice strength and lead to potential warping issues.

Securing the Runner—Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keps nut)

Beware ! Be sure your runners are through bolted to provide durability versus using screws.

LEGS

Material: The V-Series table legs are made in house from 16 gauge cold rolled steel.

Beware ! Are your table legs 16 gauge or are they 18 gauge or higher? Remember the higher the gauge the thinner the wall thickness. Do you want to sacrifice the foundation of your table for cost?

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware ! To trim cost some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Components: Rivets although small are very important to the longevity of the leg. The V-Series tables have 1/4” solid rivets to attach the bracket and hinge mechanisms. This helps assure that rivets are not breaking when the leg and hinge is constantly pivoting.

Beware ! Do the legs on your table have solid rivets or are they semi tubular rivets that are hollow and much weaker than the solid rivets? Do you want to sacrifice cost to increase the odds of the table collapsing?

Bolts (1 ¼”) using a special self locking nut (keps nut) are used to through bolt the leg to the table.

Beware ! Are your legs being through bolted for strength or being attached using only screws?

Finish is an in house powder coating which is a static electric process whereby powder is applied to the leg and is baked and cured at a high temperature.

Beware ! What type of finish is on your leg? Does it have the longevity of powder coating?

Leg End Caps are heavy duty, wear resistant and protect the floor. The caps have a special reverse metal gripping mechanism that are inserted into the leg tubing and nylon bottom for floor protection

Beware ! Are the caps being supplied with a special gripping device or being held by tension only?

EDGE MOLDING

Bullnose: Standard molding is bullnose which is referred to as rubber in the industry but is actually a vinyl product which means it is temperature sensitive. That is why we pin the vinyl molding every 12” and triple pin the corners.

Beware ! What action is being taken to assure the bullnose molding will not come loose on your table in extreme temperature changes?

C Channel: Optional aluminum T4 which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Beware ! What grade of C Channel are you being supplied? Is the channel being notched on the corners?

WARRANTY

Duration: Limited Three Year Warranty

Beware ! What is the length of your table warranty? But do you really want to deal with a warranty?

Buy a table that is made with quality materials, in such a way as to make it very unlikely that you will have to hassle with a warranty. Most warranties require you pay he shipping. Shipping can cost more than a table and it’s all an annoyance. Buy the Trident V-Series Plywood Table and avoid the hassle.

]]>

TPV-RT4096 – 8’x40″ Plywood Folding Table

The V-Series tables are Made in the USA from USA materials and will provide years of service.

Please call if your order is fewer than the minimum order quantity or more than 20 tables so we can get you a custom quote.

Quick Specs for the V-series Plywood Tables

Plywood Specifications

Type of Plywood — The V-Series uses Doug Fir known for its strength and durability. Origin of the Plywood—Western USA forests.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Domestic plywood is 23”/32”, but as a rule of thumb it is called ¾”. Normally 7 plies

Plywood used in the V series tables is Douglas Fir. 100% USA Made plywood.

The Trident V-Series Doug Fir Quick Specs

Number of plies – 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.7

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Structure is tight lay up. Each ply is cross-layered

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Compare to Common Import Specs

Number of plies – 11 – 13

Face veneer is very thin – 1/32″

Structure is not tight lay up

Not all layers of plies are cross layered

Some mills use cheaper interior glue

V-Series Plywood vs. Import pros and cons.

V series wood plies are thicker layers giving added strength

Imported thin veneers tends to delaminate and is not easily repairable like a thicker veneer.

V-Series tight lay up eliminates internal voids that may weaken the plywood and cross layering of each ply gives added strength

V-Series exterior glue is required to prevent moisture delamination. Who really knows what type of glue on imports.

Surface Finish of the Plywood

All the V-Series tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for your table. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

How Many Coats of Polyurethane?

Two coats – Polyurethane is a generic term used in the industry to describe the coating; however, Trident V-Series Tables uses an industrial lacquer. It is actually an industrial lacquer that has a catalyst added for hardness and fast drying time. After the catalyst is added the product must be used within a three (3) month period. It is an oil base that is more resistant to water; also, one (1) coat of oil base stain is applied to top and bottom of table.

What Type of Runners?

Wood Species: Runners are made from American hard wood (typically white ash, oak or beech)

Thickness: Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Securing the Runner: Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keeps nut)

The V-series table hard wood table runners are shown below, fully bolted through the top tp provide durability. Many tables use screws that are not as durable.

Above: Hard wood runners and bolted all through for strength and durability

Shown below: Strong hard wood runners on the under side of the table.

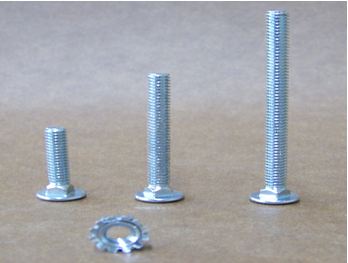

Bolts used on V-Series Plywood Folding Tables

Runner Bolts and their Length

Legs: Leg bolts on all tables are 1-1/4″

Runner Bolts:

1. On Rectangular Banquet Tables that are 6’ and 8’ the runner bolts are 2-3/16”.

2. Runner bolts on banquet tables shorter than 6’ are 3-3/16”.

3. All Round Table runner bolts are 3-3/16”.

Longer bolts are required on shorter tables because the length required to overlay legs. See picture below. All table bolts are secured with a self locking nut called a “Keps Nut”

Shown Below: Overlay means that one leg must be folded first and then the second leg must be folded to lie on top of the first leg.

What Edge Protections Are Available?

The Standard molding is a bullnose molding. Bullnose is actually a profile and is used to describe a rounded over edge. It is referred to in the industry as rubber, but ours is actually a vinyl product. Our Vinyl is tough and durable, but because vinyl is also temperature sensitive and expands with heat and contracts with cold, our craftsmen pin the vinyl molding to the table every 12” and triple pins the corners. This makes for a long lasting and durable bullnose edge.

Both moldings shown here are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood.

Shown Below: Vinyl Bullnose T-molding

Aluminum “C” Channel (shown below) is an option that some customers prefer. The V series uses aluminum T4, which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Both moldings are considered “T”-moldings because of the profile and the leg of the “T” is driven into a slot in the edge of the plywood. The aluminum edge is a highly durable and slightly more expensive edge option and must be specified on your order and upcharged. Vinyl bullnose is used as a standard option.

Folding Table Legs

All V-Series Table legs are made of 16 gauge 1” cold rolled steel. Gauge describes the wall thickness of the tube. The higher the gauge number the thinner the wall thickness.

For example 18 gauge is thinner than 16 gauge. Quality of steel in all imported items is an ongoing problem. American made steel is reliable.

Table legs get abused regularly, so it is very important to understand the components of a table leg.

Rivets (shown below) are the key in the longevity of a leg. Some manufacturers use semi-tubular rivets that are hollow and weaker than solid rivets. Solid rivets naturally cost more but are well worth the assurance that rivets are not breaking when legs and hinges are pivoting constantly. Bracket and hinge assembly is attached with 1/4″ diameter rivets. All V-Series Tables uses all solid rivets. Even the Hinge mechanism rivets are full 3/16″ diameter solid.

The Little Details, like solid core rivits (shown below) make for a High Quality Folding Leg Table.

Leg welds: (Shown Below) All cross tubes are extended through the leg tube walls and the complete circumference is welded. Some manufacturers stop the cross tube at the leg wall and this is call butt welding, meaning there is no support for the cross tube.

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware! To trim costs, some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Durable Hinge Components and Construction

Below: Hinge mechanisms are called Boss and Mate, meaning legs are locked when both open and closed. All legs are powder coated in-house. Powder coating is a static electric process whereby powder clings to the steel legs and then gets baked and cured at high temperatures to bond to the steel. Colors can be specified.

Floor Protection

Heavy duty end caps resist wear and protect floors.

This part of the table should not be overlooked, but often is. Carpet, wood floors and vinyl floors can be severely damaged with low cost caps or plugs. Check your tables regularly.

Below is a full FAQ with more info to consider.

Questions to Ask when Buying a Plywood Table

The PLYWOOD part of the story

Type of Plywood — The V-Series uses Doug Fir plywood, known worldwide for its strength and durability. Origin of the Plywood—Western USA forests.

Beware ! Your table may be made from imported plywood from an unknown Asian country or via China, which lowers the cost but sacrifices quality which leads to problems down the road.

Number of Plies — Doug Fir is 7 ply and each ply is cross layered and structured with a tight lay up to give added strength, reduce voids and reduce warping.

Beware ! Your table may have as many as 11-13 layers, not all plies being cross layered and structure of the layers not a tight lay up which leads to voids and weakens the plywood.

Plywood Thickness–3/4 inch

Beware ! Your table may be made from 5/8 inch plywood which is not as durable or as strong.

Face Veneer Thickness — 3/16 inch which means your table is repairable even after years of service.

Beware ! The face veneer on your table may be paper thin meaning it will damage easy, is non repairable and tends to warp and delaminate in damp conditions.

Type of Glue — Exterior water resistant which is required to prevent moisture delamination.

Beware ! Some imported plywood is now using interior glue.

PLYWOOD IS THE FOUNDATION OF YOUR TABLE—BE SURE YOU KNOW ALL THE FACTS. Be sure you know what you are buying—ask for a cut out sample of the plywood. If they are unwilling to supply you with the sample, maybe there is a reason.

Surface Finish of the Plywood—All the V-Series plywood tables are coated on the top and bottom with an oil base stain before applying two coats of an oil base (more water resistant) lacquer to the table top which has a catalyst added to give a harder finish, meaning better protection for the V-Series tables. The lacquer is hand rolled giving a thicker coat of protection than if applied by a UV machine.

Beware ! What chemistry is being used and how is your table being finished to assure longevity?

RUNNERS:

Wood Species — Runners are made from American hard wood (typically white ash, oak or beech)

Beware ! Are you getting runners made from hard wood or a soft species such as pine or plywood which sacrifices strength for cost?

Thickness—Runners are 1 5/8” or 2 5/8” high depending on the style of the table.

Beware ! Is the height or thickness of the runner being compromised to lower cost but sacrifice strength and lead to potential warping issues.

Securing the Runner—Runners are through bolted with 1/4” by 2 3/16” or 3 3/16” bolts depending on the style of table and the bolts are secured with a special self locking nut (keps nut)

Beware ! Be sure your runners are through bolted to provide durability versus using screws.

LEGS

Material: The V-Series table legs are made in house from 16 gauge cold rolled steel.

Beware ! Are your table legs 16 gauge or are they 18 gauge or higher? Remember the higher the gauge the thinner the wall thickness. Do you want to sacrifice the foundation of your table for cost?

Structure: A punch operation is made to the up right portion of the leg which permits the cross tubes to extend through the tube wall permitting a complete circumference weld giving added support to the strength of the leg.

Beware ! To trim cost some manufactures have eliminated the punch operation and simply stop the cross tube at the leg wall and perform a butt weld. Now the only support holding the table is a small weld.

Components: Rivets although small are very important to the longevity of the leg. The V-Series tables have 1/4” solid rivets to attach the bracket and hinge mechanisms. This helps assure that rivets are not breaking when the leg and hinge is constantly pivoting.

Beware ! Do the legs on your table have solid rivets or are they semi tubular rivets that are hollow and much weaker than the solid rivets? Do you want to sacrifice cost to increase the odds of the table collapsing?

Bolts (1 ¼”) using a special self locking nut (keps nut) are used to through bolt the leg to the table.

Beware ! Are your legs being through bolted for strength or being attached using only screws?

Finish is an in house powder coating which is a static electric process whereby powder is applied to the leg and is baked and cured at a high temperature.

Beware ! What type of finish is on your leg? Does it have the longevity of powder coating?

Leg End Caps are heavy duty, wear resistant and protect the floor. The caps have a special reverse metal gripping mechanism that are inserted into the leg tubing and nylon bottom for floor protection

Beware ! Are the caps being supplied with a special gripping device or being held by tension only?

EDGE MOLDING

Bullnose: Standard molding is bullnose which is referred to as rubber in the industry but is actually a vinyl product which means it is temperature sensitive. That is why we pin the vinyl molding every 12” and triple pin the corners.

Beware ! What action is being taken to assure the bullnose molding will not come loose on your table in extreme temperature changes?

C Channel: Optional aluminum T4 which is aircraft grade and very durable. The flexibility of the T4 aluminum allows the C channel to be applied in one piece without having to notch the corners, which maintains full strength and retention on the corners.

Beware ! What grade of C Channel are you being supplied? Is the channel being notched on the corners?

WARRANTY

Duration: Limited Three Year Warranty

Beware ! What is the length of your table warranty? But do you really want to deal with a warranty?

Buy a table that is made with quality materials, in such a way as to make it very unlikely that you will have to hassle with a warranty. Most warranties require you pay he shipping. Shipping can cost more than a table and it’s all an annoyance. Buy the Trident V-Series Plywood Table and avoid the hassle.

]]>